CNC Centre Lathes vs. Conventional Lathes: What's the Difference?

If you're interested in machines and how they work, you might have heard of Terui CNC Centre Lathes and Conventional Lathes. Both types of lathes are used to cut, shape, and materials are smooth metal or wood. However, there are some differences they are used and what benefits they offer between them can affect how. We'll explore those differences and help you decide which type of lathe best for your needs.

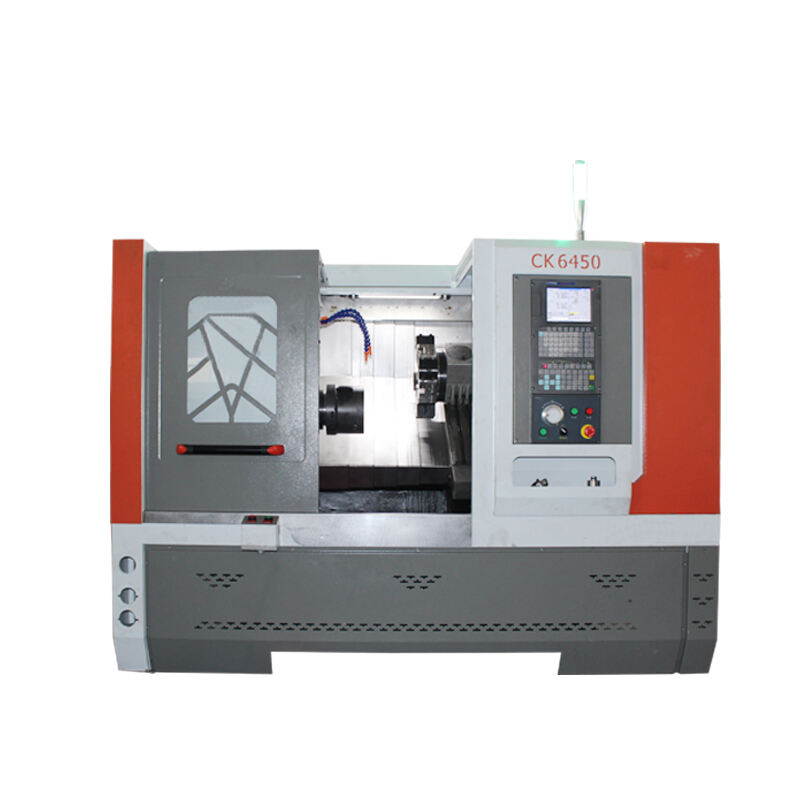

Advantages of CNC Centre Lathes

CNC stands for Computer Numerical Control. This means CNC Centre automatic lathe are controlled by a computer program tells the machine what to do. This offers some advantages are major conventional lathes:

- Precision: Since the computer controls the movements of the machine, CNC Centre Lathes can be incredibly precise, cutting to within a few thousandths of an inch. This accuracy important for industries like aerospace or device medical, where even tiny imperfections can cause problems are big.

- Efficiency: Because the CNC program pre-written to cut the material in a way certain there no need for manual adjustments or guesswork. This can make the cutting process much faster and more efficient.

- Consistency: Once the CNC program set up, the machine will cut the material the way same time, producing consistent results. This especially important for mass production of parts or components.

Innovation in CNC technology

One of the biggest advantages of CNC technology its ability to adapt to challenges are new opportunities. As new materials and designs become available, CNC machines can be reprogrammed to cut them in new and ways are exciting. This means cnc and lathe can stay relevant and useful for many years, even as technology continues to evolve.

Safety considerations

CNC Centre Lathes offer some safety benefits over conventional lathes. Since a computer controls the machine, there less risk of human error accidents are causing. Some CNC Centre Lathes are equipped with safety features like automatic shut-off switches can stop the machine if anything goes wrong.

How to use CNC Centre Lathes?

Using a CNC Centre Lathe requires some knowledge specialized but it not as difficult as you might think. Here are the steps are basic

- Create a design: you need to create a design in a CAD (Computer-Aided Design) program before you can cut anything. This program shall output a file the CNC machine can read and understand.

- Create a CNC program: Using CAM (Computer-Aided Manufacturing) software, you can take your model and turn it into a set of instructions the CNC machine can follow.

- Load the material: Once the program created, you will need to load the material you want to cut into the machine.

- Run the program: After selecting the program you want to run, the CNC machine will start cutting the material automatically.

Service and quality of CNC Centre Lathes

Like any machine, cnc automatic lathe require maintenance and upkeep to smoothly keep them running. However, because the machine controlled by a computer, it can often alert users to problems are potential they become serious. The consistency and precision of CNC Centre Lathes can result in higher-quality parts and components, leading to better results are overall your project.

Application of CNC Centre Lathes

CNC Centre Lathes are used in a range wide of, from aerospace to automotive to device manufacturing medical. They are especially useful for mass-producing parts or components require a degree high of and consistency. For example, a CNC Centre Lathe might be used to create a set of perfectly gears are identical a car's transmission, or to produce thousands of precisely-cut components for medical equipment.

Conventional Lathes and their advantages

Conventional Lathes, on the other hand, are not controlled by a computer program. Instead, they are operated manually, and the machine operator makes adjustments to the tool cutting needed. While this might seem less efficient or precise than a CNC Centre Lathe, there are some advantages to lathes are conventional

- Flexibility: Because the machine operated by a human, it can be adjusted on the fly to cut materials in different ways. This can be useful for small-scale prototyping or other projects require a complete lot of experimentation and tinkering.

- Simplicity: Conventional Lathes are simpler in design than CNC Centre Lathes, which means they may be easier to use or repair for some users.

EN

EN