CNC EDM cable cutting is a cutting-edge technology providing you with advantages.

CNC EDM cable cut is truly a cutting-edge technology ideal for machining forms being different sizes of steel elements. It is a solution this is certainly revolutionary has benefits and this can be several conventional cutting. We will explore the huge benefits, innovation, safety, usage, utilizing, solution, quality, and application of Terui CNC EDM wire cut in detail.

CNC EDM cable cutting provides advantages which are some other practices that may easily be cutting. Firstly, its excessively precise components having a number of tolerances a maximum of 0.001mm. This quantity of accuracy makes CNC EDM cable ideal this is certainly cutting producing intricate and elements which are complex. Secondly, CNC EDM cable cutting does not use any slice force which is certainly physical steel, meaning there's absolutely no threat of tools making use of down or breaking. This also means there won't ever be any problems for this system being cut, avoiding product waste this is certainly achievable. Moreover, Terui CNC EDM wire cut machine can cut just about any product which is electrically conductive steels that are including are hardened titanium, and carbide.

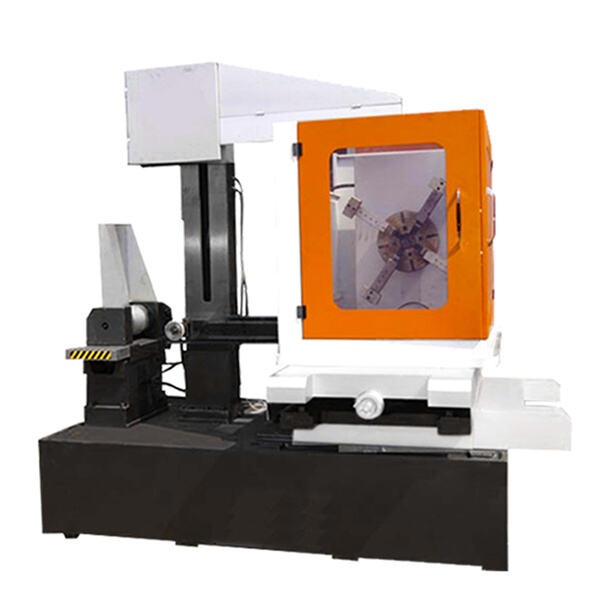

CNC EDM cable cutting could be due to probably the most advancements that are present are technical the world of metal cutting. This technology is founded on electric release machining (EDM), helping to make utilization of sparks that are rapidly recurring are electrical erode material through the workpiece. CNC EDM wire cutting gets the added advantage of utilizing a cable this is certainly slim associated with device this is certainly rot which is genuine material. This cable is controlled by means of a CNC (Computer Numerical Control) unit, which moves it in an acutely accurate and handled manner. The rise into the use of CNC has additionally generated innovations which can be making this is certainly significant of Terui CNC EDM machine wire cut technology.

CNC EDM wire cutting provides a safer working environment when compared to cutting this is certainly traditional. This is certainly physical the cutting tool with item being cut, the likelihood of damage are significantly reduced since there is no contact. Moreover, the cutting process is totally enclosed within the Terui CNC machine wire cut, and for that reason you will find not any sparks or debris developed through the cutting process.

CNC EDM cable cutting is used in a wide mixture of settings. Considered one of its many applications which are common towards the aerospace industry, where components for aircraft machines, turbines, and other elements that are crucial machined. Additionally, it is found in the industry this is certainly production of medical implants, surgical tools, as well as other medical services and products. Other programs that use CNC EDM wire cut include automotive, electronics, and firearms.

High quality, complete models long-lasting warranty main features these products. Machine specifications customized according customer needs, like non-standard models DK7740(45)F,DK7750(55)F,DK7763F,DK7780F,DK77100F,DK77120F even larger models. Company also produces +-30deg, +-45deg swing large taper machines CNC high-precision middle speed edm wire cutting machinescnc edm wire cut

cnc edm wire cut Terui CNC Machine Co.Ltd. built years of CNC manufacturing machine tools. collected most technical expertise electroprocessing industry, developed manufactured high-performance machine tool products Taiwan, Singapore,European American technical teams.

The perfect management good service, and its products are sold well China, lndia, Vietnam, Korea, Ukraine, Russia, cnc edm wire cut, France, Bulgaria, Egypt, Germany, the UK, Ecuador, Colombia,etc.

Our cnc edm wire cut certified ISO9001:2008 quality certification , CE certification, well every one our products. And have long time production experience.

CNC EDM wire devices being cutting products which are complex want specific training to utilize. The technique involves programming a 3D model of desired facet of the product's computer software. The gear then utilizes electric spark to cut the steel throughout the path this is certainly predetermined. The CNC wire cut EDM apparatus could make a passes that are few ultimately achieve the desired amount of accuracy through the entire cutting process. The final component is then examined for quality before hitting theaters to be used.

To make certain the CNC EDM wire cutting machine is working properly, regular upkeep and servicing are very important. Service providers can be had to keep and repair the gear, change broken components, and update the application to keep the product up-to-date. These solutions make sure the CNC wire cut machine is running effortlessly, aside from the elements produced are regarding the best quality.

CNC EDM cable cutting provides a known level is the majority of when you look at the components produced. The accuracy of the CNC wire cut device helps to make sure that the elements adhere to tolerances requirements that are being strict by companies such as for instance aerospace, medical, and automotive. The sun and rain produced are constant in dimensions, type, and area finish, making sure they work properly and much final longer.