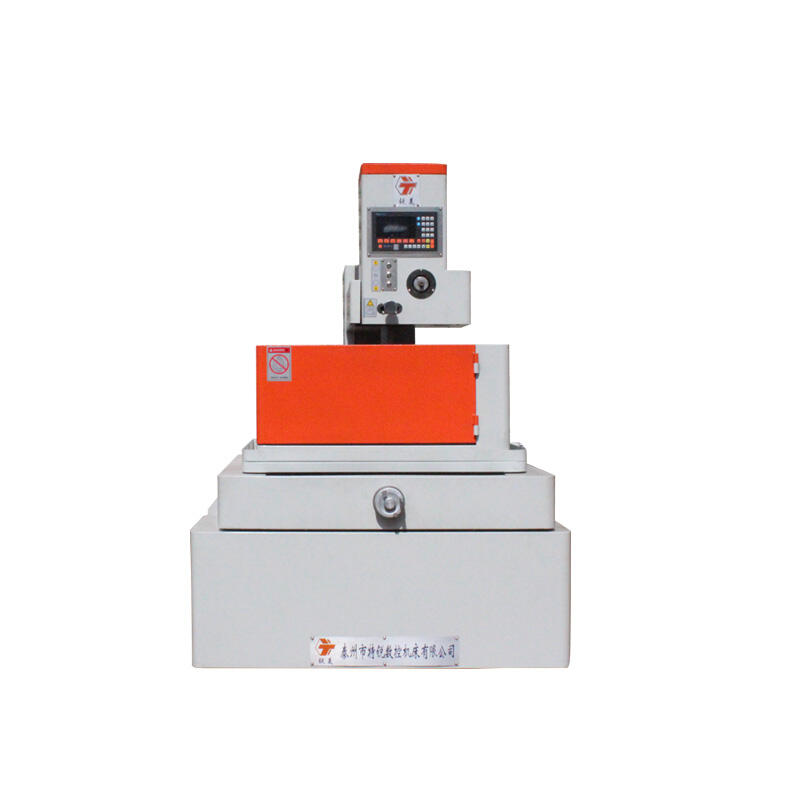

Middle speed wire EDM

With many years of R&D history and rich manufacturing experience,Terui CNC perfectly integrates the

slow-moving wire EDM technology into the newly developed middle speed wire EDM,making its

performance reach an unprecedented level.

Description

T-shaped bed, C-shaped integral column

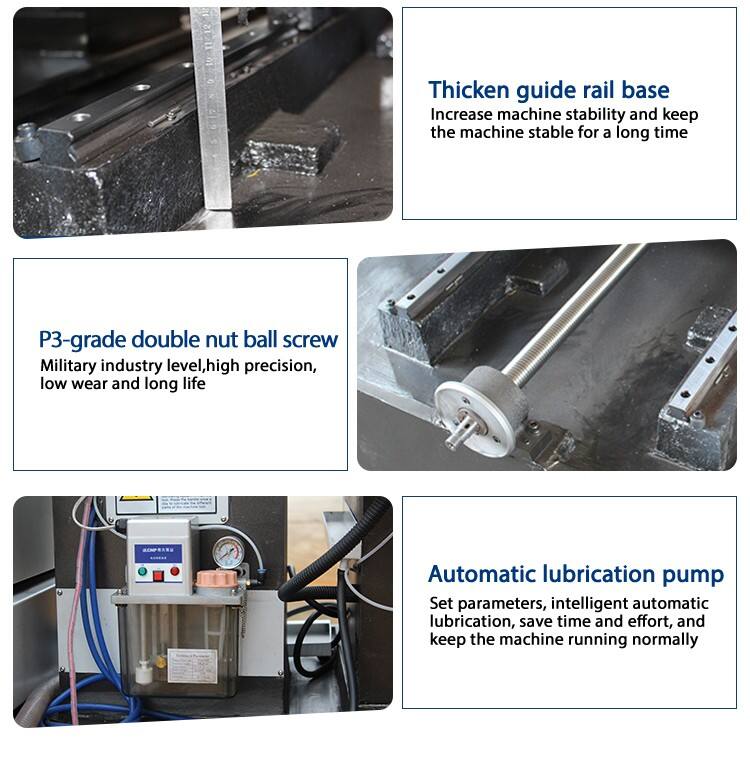

The main shaft is designed with three-dimensional solid modeling,which is guaranteed by finite element force analysis and sufficient experiments to ensure sufficient rigidity. High-strength resin sand castings are used for key castings such as bedcarriage,and column,which are designed as large and thick-walled box castings to make the bed with sufficient rigidity and strength. At the same time,the castings are de-fired and naturally aged to remove stress to ensure that the machineis resistant to fatigue and does not deform.

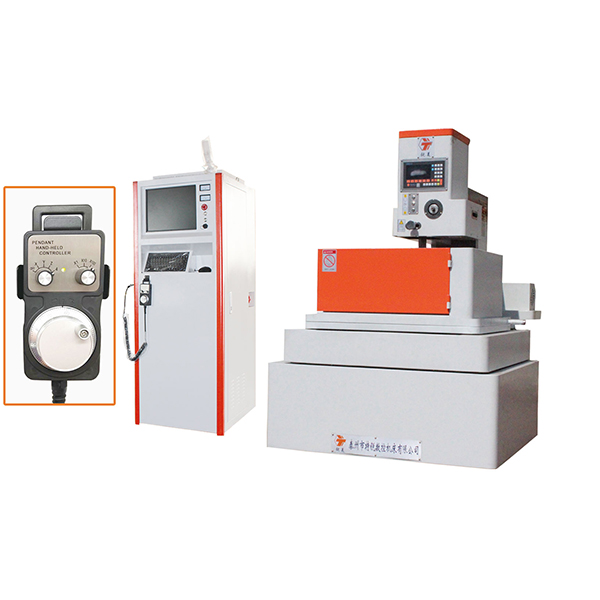

Fully intelligent control cabinet with expert data

The fully intelligent control cabinet ensures stable and reliable long-term performance. The imported AC servo system is adopted to make the processing speed faster and the multiple cutting precision higher.It supports Dwg,dxf, 3B,G code and other format code conversion, which is convenient for data exchange. The data is fully intelligently generated, and the expert database with super humanized design can be processed with one click,which directly reduces the workload of the operator, and is simple and convenient to operate.

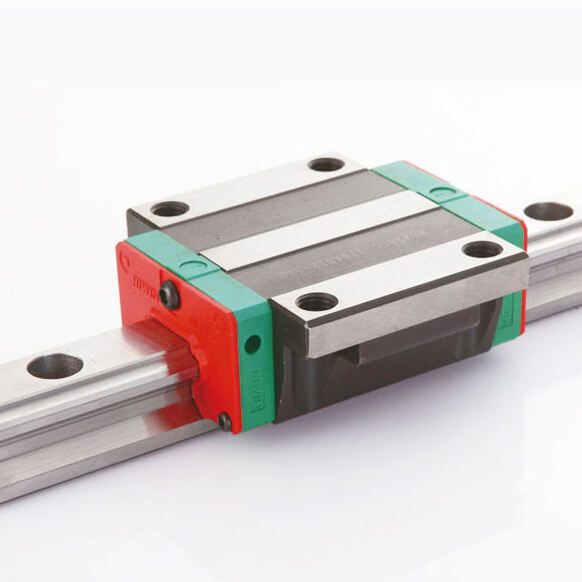

High-quality parts are adopted

Combining high-precision Taiwan HWIN linear guide,China North Machinery P3 level lead screw,various high-quality parts and pitch compensation function,the machine’s mechanical precision achieves the effect of slow-moving wire EDM.The new splash-proof design can effectively block and reduce the splash of cutting fluid and keep the processing environment clean.

There is a rockable hand wheel on the fully intelligent control cabinet of

the servo middle wire edm, with a built-in special servo driver for controlling

the XY axis motor operation. It is simple and convenient to use without effort.

This accessory is a standard configuration for the servo model.

Specifications

| Model | Unit | TRS-32 | TRS-33 | TRS-50 | TRS-63 |

| Worktable travel | mm | 320*400 | 400*500 | 500*630 | 630*800 |

| Max cutting thickness | mm | 380 | 380 | 380 | 380 |

| Max taper | ° | 6°/80 | |||

| Accuracy | mm | ≤0.01 | |||

| Best roughness | um | ≤Ra1.2 | |||

| Max speed | mm²/min | ≥160 | |||

| Max load | kg | 300 | 380 | 700 | 1000 |

| Weight | kg | 1400 | 1600 | 2300 | 2800 |

| Dimensions | mm | 1650*1200*1900 | 1740*1330*2200 | 2000*1680*2250 | 2100*1940*2250 |

Details

EN

EN