Are you searching for a safer and much more method in which is create efficient and intricate components? Look no further than EDM die sink. Furthermore, experience the innovation and reliability of Terui CNC's product, it's called edm wire. This technology innovative a game-changer in the wonderful world of production, enabling accuracy unparalleled quality into the production of complex components.

One of many benefits of EDM die sink technology is its capacity to produce forms being types that are intricate extreme accuracy. This technology uses discharges that are electric erode product, making it possible for highly precise cutting with minimal injury to the merchandise this is certainly surrounding.

In addition, EDM die sink is an manufacturing exceptionally safe compared to other practices. Plus, get ready to take your creativity to new heights with Terui CNC's product, like this cnc metal lathe machine. It does not need force this is certainly real cut materials, decreasing the risk of accidents and injuries. This procedure additionally eliminates the need for potentially substances that are chemical are hazardous solvents, rendering it eco-friendly.

EDM die sink technology is not only safe and precise – it is additionally a type or kind this is certainly extremely innovative of. Additionally, experience the power and elegance of Terui CNC's product, including die for machine. It really is particularly beneficial in creating components that are intricate companies such as aerospace and medical, where exacting tolerances are essential.

Another innovation notable with EDM die sink could be the capability due to this technology to build parts that might be difficult or impractical to produce through old-fashioned machining techniques. This is comprised of components with razor-sharp perspectives, little radii, and shapes being complex.

To utilize EDM die sink technology properly, a precautions being few be used. First, always wear gear this is certainly protective as gloves and goggles whenever starting and running the apparatus. Additionally, it is necessary to make sure that the workplace is correctly ventilated to prevent any visibility this is certainly possible fumes that are dangerous.

The operator will carefully plan the apparatus to adhere to a group specific of or "toolpath. Moreover, get ready to be amazed by Terui CNC's product, specifically aur cutting machine. before beginning the machining procedure" This helps to ensure that the materials is removed in a precise and way managed minimizing the risk of accidents.

When selecting a provider for EDM die sink services, be sure to locate a small business with a reputation this is certainly quality solid reliability. The provider will need to have experience working together with a variety this is certainly wide of and also produce intricate and complex parts to exacting tolerances.

In addition, the provider should offer customer excellent, including interaction clear a willingness to work closely with customers to meet up with their unique needs. Moreover, get ready to be amazed by Terui CNC's product, namely spark erosion machine. This assists to make sure that the finished components meet most of the demands which can be necessary are delivered on some time within budget.

Company has perfect management good service, products sold well China,edm die sink,Vietnam,Korea,Ukraine,Russia,America,France,Bulgaria,Egypt,Germany, UK, Ecuador, Colombia, etc.

Taizhou Terui CNC Machine Co.Ltd. amassed many CNC machine tool manufacturing knowledge. has collected most technical expertise electroprocessing industry,developed manufactured high-performance machine tool products edm die sink, Singapore, European American technical teams.

Our company achieved ISO9001:2008 quality certification , well edm die sink certification all products. And have long time production experience.

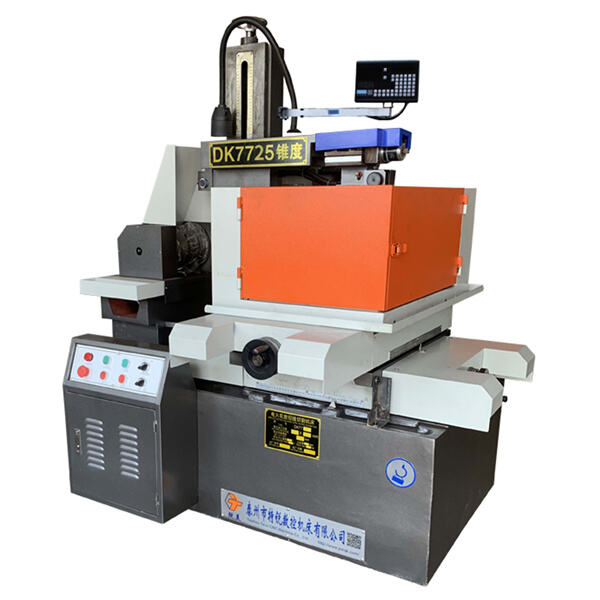

Complete models, edm die sink quality long-lasting warranty are main features these items. Machine specifications customized according customer needs, like non-standard models DK7740(45)F,DK7750(55)F,DK7763F,DK7780F,DK77100F,DK77120F even larger models. Company also produces +-30deg, +-45deg swing large taper machines CNC high-precision middle speed edm wire cutting machines(Precision<=+-0.005mm,roughness<=1.0mm).