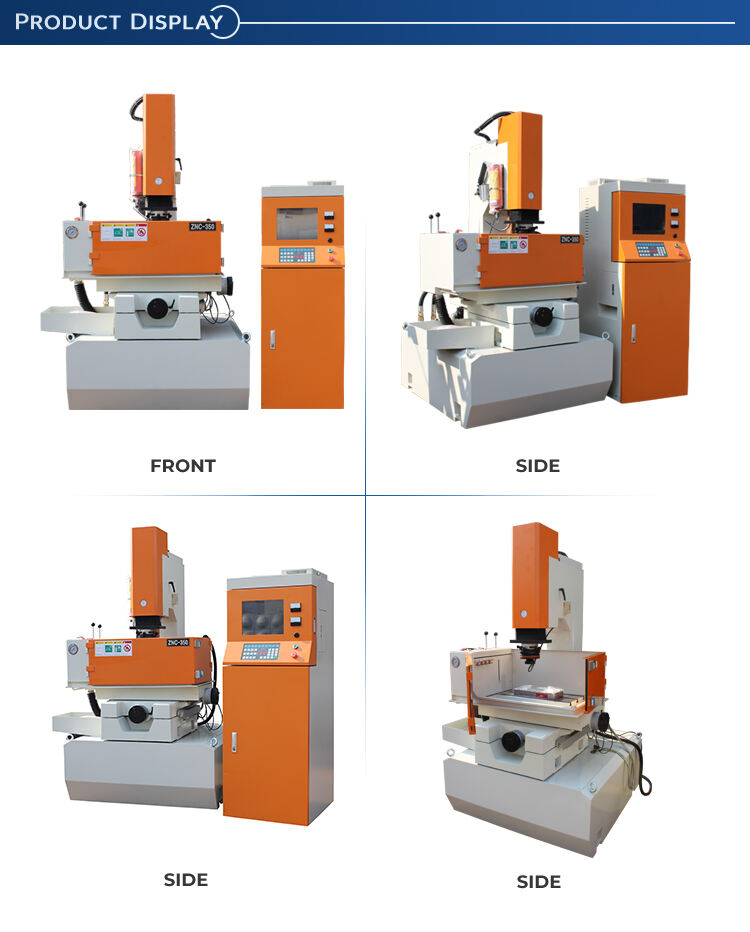

Description

High rigidity mechanical structure and humanized design;

Processing deep holes, superhard materials and other functions to meet the needs of various molds;

Ten stages of programmable processing,from coarse to fine,can be completed at one time, which is convenient and flexible;

The easiest operation interface,suitable for all levels of personnel;

The unique two-stage settable servo system greatly improves the processing efficiency;

The computer built-in expert system can minimize the electrode loss; Ultra-fine machined surface with mirror machining loop;

High-sensitivity anti-carbon deposition circuit ensures no arcing phenomenon;

Multiple fire extinguishing safety protection devices to ensure safe and reliable use;

Modular electrical design, extremely low failure rate, easy to upgrade.

Specifications

| Model | ZNC-350 | ZNC-450 | ZNC-550 | ZNC-650 |

| Worktable size(mm) | 600*300 | 700*400 | 800*480 | 1000*600 |

| Working slot size(mm) | 820*500*300 | 1120*620*420 | 1290*770*550 | 1700*1000*620 |

| X(mm) | 350 | 450 | 550 | 650 |

| Y(mm) | 250 | 350 | 450 | 550 |

| Z(mm) | 200 | 200 | 250 | 250 |

| Spindle head travel(mm) | 200 | 200 | 300 | 300 |

| Max electrode weight(kg) | 60 | 70 | 200 | 200 |

| Max load(kg) | 500 | 750 | 1500 | 2250 |

| Electrode plate to table(mm) | 150-550 | 200-600 | 160-710 | 260-860 |

| Tank capacity(L) | 280 | 300 | 470 | 940 |

| Dimensions(mm) | 1320*1220*2100 | 1470*1380*2100 | 1600*1400*2500 | 1920*1800*2500 |

| Weight(kg) | 1300 | 1650 | 3200 | 3600 |

| Electrical cabinet | P30A/P30B | P60A/P60B | P90A/P90B |

| Max current(A) | 30 | 60 | 90 |

| Max power consumption(KDA) | 2 | 4 | 6 |

| Max speed(mm³/minute) | 200 | 400 | 600 |

| Min electrode consumption(%) | 0.8 | ||

| Best roughness(μm) | Ra≤0.8 | ||

| Dimensions(mm) | 600*800*1800 | 300*800*1800 | 600*800*1800 |

| Weight(kg) | 190 | 210 | 230 |

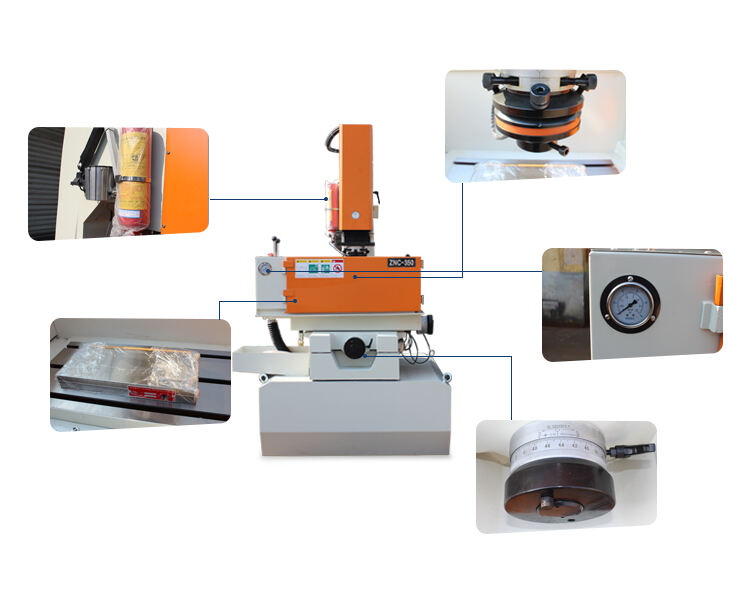

Details

EN

EN