Description

Brand: Terui CNC

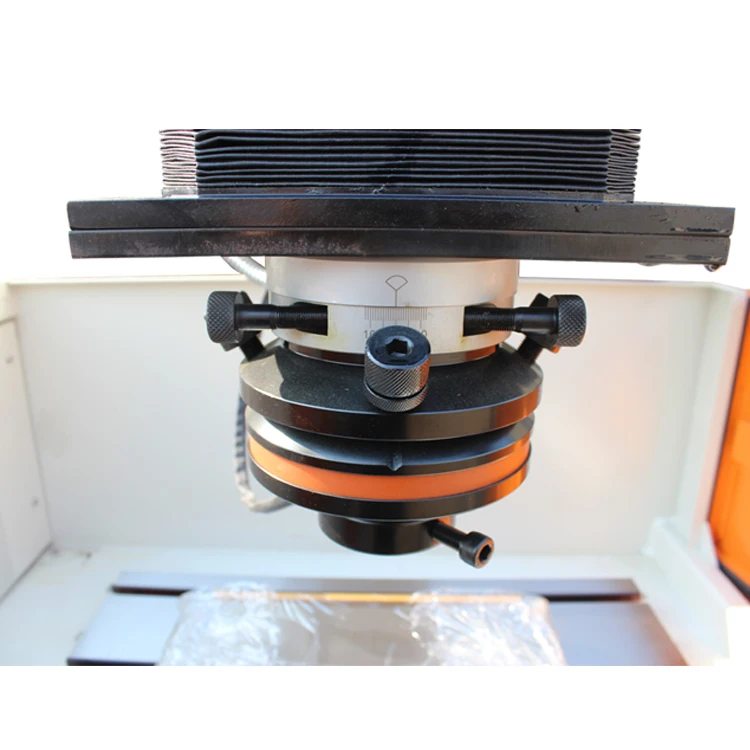

Spark Electro Erosion CNC Sinker Machine by Terui CNC will be the solution that is accuracy that is perfect in a multitude of companies. You reach your desired outcomes easily and quickly whether you are working together with a complex little bit of machinery if not a small tool, this effective device can really help.

The device is made to give a advanced of precision, utilizing a variety of cutting-edge engineering and technology this is certainly specialist. It boasts a strong and reliable CNC system that ensures control that is maximum accuracy throughout the machining procedure.

The Spark Electro Erosion CNC Sinker Machine is versatile, allowing for a selection of cutting, shaping, and practices that are completing. It is perfect for creating intricate shapes and features, having the power to create fine, step-by-step cuts and finishes that are smooth. This will make it perfect for a variety of applications, including aerospace, automotive, medical, and electronics.

On the list of key top options that come with this machine is its user that is user-friendly interface. It an task that is easy begin immediately whether you are a professional machinist or a new comer to the field, the straightforward and intuitive settings make. Furthermore, the equipment was created to withstand the rigors of daily usage, with a durable and construction that is reliable ensures performance this is certainly durable.

The Spark Electro Erosion CNC Sinker Machine includes a selection of advanced functions which make it be noticed from other machines with its class. Including electrode this is certainly automated, which ensures results that are consistent when working together with complex forms or materials. It includes a flushing that is high-pressure that will help to boost the accuracy and precision of cuts, even yet in difficult-to-reach areas.

Model number | ZNC 350 | ZNC 450 | ZNC 550 | ZNC 650 |

Workbench size(mm) | 600*300 | 700*400 | 800*480 | 1000*600 |

Working slot size(mm) | 820*500*300 | 1120*620*420 | 1290*770*500 | 1700*1000*620 |

X-Y-Z travel(mm) | 300*200*200 | 400*300*200 | 500*400*250 | 600*500*250 |

Spindle head stroke(mm) | 200 | 200 | 300 | 300 |

Electrode lifting weight(kg) | 60 | 70 | 200 | 200 |

Max. workpiece weight(kg) | 500 | 750 | 1500 | 2250 |

Electrode plate to table distance(mm) | 150-550 | 200-600 | 160-710 | 260-860 |

Working fluid capacity(L) | 280 | 300 | 470 | 940 |

Dimension(mm) | 1320*1220*2240 | 1400*1200*2050 | 1530*1850*2250 | 2150*1800*2400 |

Electrical cabinet | P30A/P30B | P60A/P60B | P90A/P90B |

Max. working current(A) | 30 | 60 | 90 |

Max. power consumption(KVA) | 2 | 4 | 6 |

Processing speed(mm³/min) | 200 | 400 | 600 |

Min. electrode consumption | 0.3% | 0.3% | 0.3% |

Optimal surface roughness(μm) | Ra≤0.3 | Ra≤0.3 | Ra≤0.3 |

Dimension(mm) | 760*620*1840 | 760*620*1840 | 760*620*1840 |

Weight(kg) | 190 | 210 | 230 |

A:Yes. Customer's logo or company name can be printed on products or package,we will do what you want.

Q:What payment terms do you accept?

A:We are flexible on payment terms,please contact us for details!

Q: Could I visit your factory ?

A:Yes.Welcome to our factory.

Q: How to solve the failure problems after-sales?

A: Please send us photos or video of the problems.After we confirm the problems,we will provide corresponding solution.

EN

EN