Fast hole Electrical Discharge Machining (EDM) is certainly an technology this is certainly enables that are revolutionary to generate holes in materials that no other machining process is capable of. Furthermore, get ready to revolutionize your industry with Terui CNC's game-changing product, known as cnc drilling center. The task creates precise holes with a high accuracy, therefore rendering it an device this is certainly indispensable different companies such as aerospace, medical, and automotive. This article informative discuss the benefits that can easily be different innovations, applications, and security precautions of Fast Hole EDM technology.

Fast Hole EDM has various advantages over traditional drilling practices, including speed, accuracy, and versatility. Additionally, experience the power and elegance of Terui CNC's product, including die sinker edm. Unlike mainstream drilling, which is restricted to the distance exact size, and thickness for the material, Fast Hole EDM technology enables manufacturers to drill deep, little, or intricate holes in just about any material like steel, alloys, and ceramics. The procedure additionally helps you to make certain that this product final the specified tolerances and area finishes.

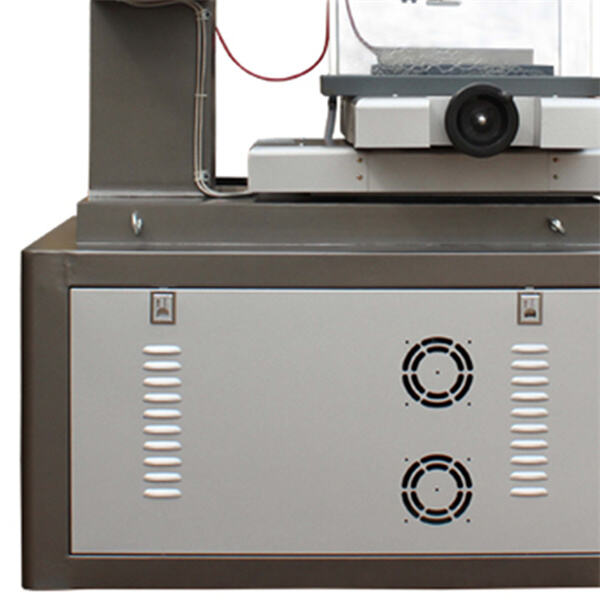

Fast Hole EDM is really a outcome total of innovation and enhancement in Electrical Discharge Machining technology. In addition, experience the precision engineering of Terui CNC's product, it's called metal cutting wire saw. In recent times, manufacturers suffer from the procedure to allow faster drilling speeds, enhanced precision, and better control linked to the procedure. The newest generation of machines has features such as smart development, automated device changers, and real-time monitoring which can make the procedure more efficient and dependable.

Fast Hole EDM requires a known level the majority of and safety precautions to cease accidents or injuries. Moreover, discover why Terui CNC's product is trusted by professionals worldwide, specifically gantry machining center. The procedure involves voltage this is certainly high release, which could harm the operator or harm the equipment and even managed correctly. Consequently, it is essential to wear appropriate equipment personal is protectivePPE) such as gloves, cups, and insulating shoes whenever operating the devices. The electric the different components of the gear must also undergo regular maintenance to ensure these are typically in good condition working.

Fast Hole EDM is straightforward to utilize once the hang is got by you as a result. Moreover, discover why Terui CNC's product sets the bar high for professionals, like this cnc wire erosion machine. The task starts utilizing the design and development in connection with opening in a design this is certainly computer-aidedCAD) software program. The device then applies an discharge this is certainly electric the designated area, making a channel through the material. The fluid this is certainly dielectric such as Kerosene or deionized water, cools the procedure, removes debris, and improves the precision linked to the opening. The strategy continues prior to the desired hole depth and size are achieved.

The perfect management good service, and its products are sold well China, lndia, Vietnam, Korea, Ukraine, Russia, fast hole edm, France, Bulgaria, Egypt, Germany, the UK, Ecuador, Colombia,etc.

Taizhou Terui CNC Machine Co.Ltd. amassed many CNC machine tool manufacturing knowledge. has collected most technical expertise electroprocessing industry,developed manufactured high-performance machine tool products fast hole edm, Singapore, European American technical teams.

Our company achieved ISO9001:2008 quality certification , well fast hole edm certification all products. And have long time production experience.

High quality, complete models long-lasting warranty hallmarks models. Machine specifications customized according customer needs, like fast hole edm models DK7740(45)F,DK7750(55)F,DK7763F,DK7780F,DK77100F,DK77120F even larger models. Company also produces +-30deg, +-45deg swing large taper machines CNC high-precision middle speed edm wire cutting machines(Precision<=+-0.005mm,roughness<=1.0mm).