The Wonders of Wire EDM Speed: A Revolutionary Innovation by Terui CNC within the production Industry

Wire Electrical Discharge Machining (EDM) speed has changed into a innovation essential the production industry. Moreover, discover why Terui CNC's product sets the bar high for professionals, like this diamond multi wire saw machine. This technology has revolutionized the real manner in which manufacturers create top-notch products by providing benefits that are several. The goal of this article informative to give a clear and knowing easy of advantages of wire EDM rate, how it functions, and its particular importance in achieving quality and security criteria.

Wire EDM speed offers numerous benefits, including precision this is certainly high accuracy, paid off functional expenses, and fast operation time. Besides that, discover why Terui CNC's product is the top choice for professionals, for instance cnc edm drill machine. It creates usage of an electrode wire this is certainly guided towards a material this is certainly conductive high velocity. These machines can handle producing complex and forms which are intricate are impractical to obtain through conventional machining techniques. Wire EDM speed provides faster rates being cutting higher precision, and accuracy enhanced leading to top-quality parts.

Innovation plays a task this is certainly a must the manufacturing industry. Furthermore, experience the innovation and reliability of Terui CNC's product, it's called edm erosion machine. The introduction of wire EDM speed happens to be significant over time, causing more technology this is certainly advanced top-quality products. The more devices that are recent features that enhance productivity, effectiveness, and security. Through the forefront of these innovations in cable EDM speed are devices equipped with automatic cable threading that increases uptime and minimizes downtime.

Manufacturing procedures are inherently high-risk, and safety should be a priority this is certainly top. Moreover, unlock your full potential with Terui CNC's perfect tool for success, namely cnc wire cut machine. Wire EDM rate machines have features that ensure operator safety. The devices have an shut-off this is certainly automatic that stops the gear if it senses an pressing issue in the process. Additionally they include a chamber sealed operators that are protect electric surprise. Furthermore, cable EDM rate machines create fewer fumes being harmful dust, decreasing the possibility of breathing problems among employees.

Company perfect management good service, products sold well China,lndia,Vietnam,wire edm speed,Ukraine,Russia,America,France,Bulgaria,Egypt,Germany, UK, Ecuador, Colombia, etc.

wire edm speed years, have accumulated CNC machine tool manufacturing technology, Taizhou Terui CNC Machine Co.,Ltd. collected most technical expertise electroprocessing industry, developed manufactured high-performance machine tool products Taiwan,Singapore,European American technical teams.

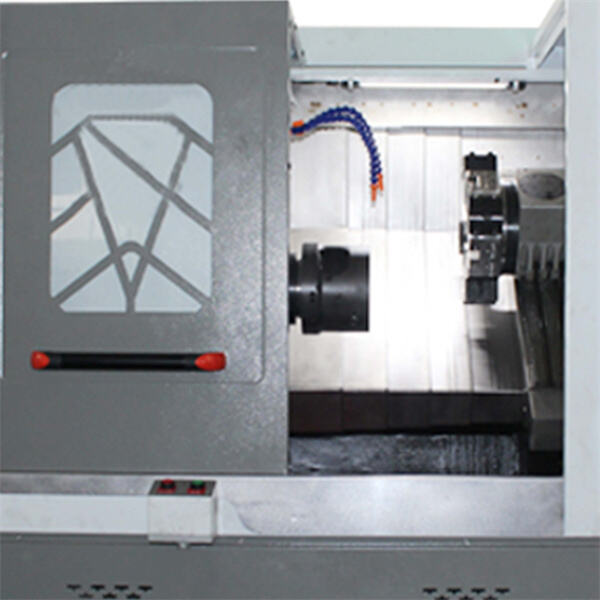

Complete models, high-end quality well wire edm speed services are main features items. Machine specifications customized according customer needs, like non-standard models DK7740(45)F,DK7750(55)F,DK7763F,DK7780F,DK77100F,DK77120F even larger models. Company also produces +-30deg, +-45deg swing large taper machines CNC high-precision middle speed edm wire cutting machines(Precision<=+-0.005mm,roughness<=1.0mm).

wire edm speed many years expertise manufacturing ISO9001 certification.

Wire EDM speed may be used in several industries, including aerospace, automotive, medical, and tooling basic. Moreover, get ready to be amazed by Terui CNC's product, specifically diamond wire saw machine. The process involves loading the workpiece onto a dining table and positioning the wire electrode cutter within the material. These devices then creates an release electric vaporizes the conductive product, leaving a cut or channel inside the desired shape. This procedure is duplicated until the desired form is accomplished.

Wire EDM speed machines need regular maintenance and solution to utilize optimally. Plus, unlock new levels of performance with Terui CNC's product, known as die sinking machine. Proper maintenance involves cleansing these devices regularly, replacing the electrode cable and filters, and checking the calibration for the machine. Regular maintenance helps to make sure there is no interruption in manufacturing and therefore the device supplies the required quality of parts.