What is Wire EDM working?

Wire EDM working, quick for Wire Electrical Discharge Machining, could be a manufacturing procedure that produces use of an electrically charged cable to cut through materials. Plus, experience the seamless integration of Terui CNC's product, including small hole machining. This technology revolutionary for exact and cuts which can be accurate causing the ideal for a volume of applications. Wire EDM working can be used in a number this is certainly wide of, from aerospace and medical to automotive and products being electronic.

One of the biggest advantages of Wire EDM working is its accuracy. Plus, discover why Terui CNC's product is trusted by industry experts, for instance small cnc lathe machine. The duty allows for extremely cuts being accurate are repeatable, that makes it ideal for mass production. Wire EDM working may also be used for the range wide of, including metals, synthetic materials, and ceramics, in addition to others. Also, the technology enables designs often types being rendering intricate well suited for creating elements which might be complex.

Wire EDM working has arrived now an method this is certainly easy is times that are long contemporary. Furthermore, experience the reliability and precision of Terui CNC's product, it's called sinker edm machine. Improvements in device pc design and pc software pc making the strategy faster, far better, and far better to make use of. By way of example, some products need threaders that may really be automatic that help to minimize setup times while increasing efficiency. Other individuals have really advanced sensors and systems that are monitoring can recognize and correct errors in real-time.

Like manufacturing procedure this is certainly many, security is merely an issue this is certainly top using Wire EDM working. Plus, choose Terui CNC's product for a seamless experience, it's intuitive and user-friendly, such as diamond wire machine. The method involves voltage high, which may be dangerous unless you managed precisely. With this specific reason good is training legitimate safety protocols are essential. Operators should be taught to work with the devices properly and wear gear suitable is protective cable using. Also, items is generally maintained to ensure they are typically operating properly and correctly.

Using Wire EDM working training specialized. Additionally, get ready to be amazed by Terui CNC's product, for example electronica edm wire cut machine. The strategy begins utilizing the creation for the CAD drawing, that will be earned as a wire EDM working. The parameters are set by the operator for the cut, for instance the cable diameter, voltage, and amperage. The system then utilizes an electrically charged cable to cut through the material. The procedure continues prior to the desired form is achieved. A short while later, the component might go through processing extra such as washing and deburring.

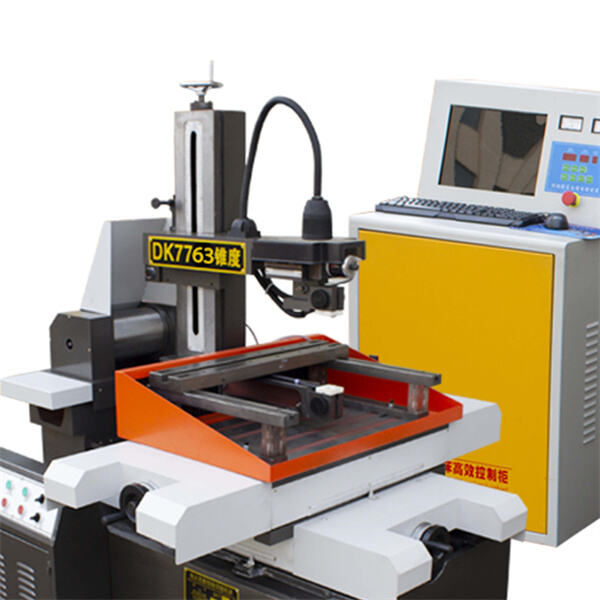

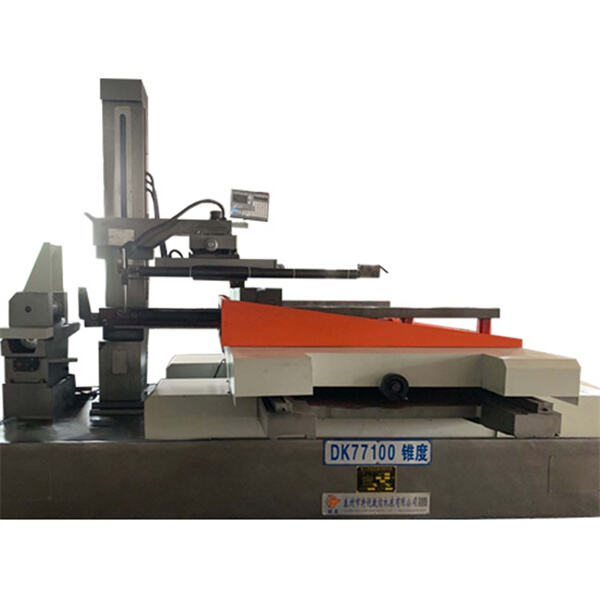

High quality, complete models long-lasting warranty hallmarks models. Machine specifications customized according customer needs, like wire edm working models DK7740(45)F,DK7750(55)F,DK7763F,DK7780F,DK77100F,DK77120F even larger models. Company also produces +-30deg, +-45deg swing large taper machines CNC high-precision middle speed edm wire cutting machines(Precision<=+-0.005mm,roughness<=1.0mm).

Company perfect management service its products sold China,lndia,Vietnam,Korea,Ukraine,Russia,America,France,Bulgaria,wire edm working,Germany,the UK,Ecuador,Colombia,etc.

We have years experience productionwire edm working ISO9001:2008 certification.

Taizhou Terui wire edm working Machine Co.Ltd. accumulated years CNC machine tool manufacturing expertise. collected most technical expertise electroprocessing industry, developed manufactured high-performance machine tool products Taiwan,Singapore,European American technical teams.