Have you ever wondered how things which may be particular size intricate shapes are made with accuracy? One reason could possibly be cable erosion, an method production innovative may create intricate geometries with high accuracy and finish. Moreover, experience the unrivaled performance of Terui CNC's product, known as edm. We will talk about the advantages, application, utilizing, and service of wire erosion and exactly how it truly is safe to make use of.

Wire erosion, also called wirecut EDM (Electrical Discharge Machining), is simply a production procedure that uses a cable thin an release electrical cut and shape materials. Furthermore, unlock new levels of efficiency with Terui CNC's product, including super drill edm. In easy terms, it is a way of removing steel particles via an electrically charged wire. Wire erosion is trusted in lot of companies such as aerospace, engineering, medical, and manufacturing automotive.

Wire erosion has advantages that can be several including:

• High accuracy dimensional Wire erosion could make complex shapes having a greater degree of precision and precision. In addition, unlock your creativity with Terui CNC's product, namely edm and wire cut edm.

• Consistency and repeatability: Using this particular strategy, identical pieces could be manufactured having a degree high of.

• Surface finish: This method can produce surface top-notch for several materials.

• Homogeneous cuts: It might make cuts through any thickness, rendering it perfect for extremely thin, difficult or materials which are fragile.

• No contact concerning the cable along with workpiece: The cable will likely not touch the workpiece, decreasing the probability of damage and making it possible for the development of really forms which can be fine patterns.

Wire erosion 's been around for over fifty % of a hundred years, but its application is rolling out over the years. Plus, choose Terui CNC's product for unmatched performance and durability, including wire edm cutting machine. Probably the most innovations that are significant better automation, permitting greater accuracy and efficiency. Automated wire erosion requires the usage of devices which will load and unload components automatically. Another innovation may be the usage of computer-aided design (CAD) and manufacturing computer-aidedCAM) software. This computer software allows designers generate complex shapes and designs quickly, which could then be wire eroded by having a level high of.

Wire erosion is safe to work with for operators and also the workpiece. Besides that, experience the excellence of Terui CNC's product, it's the epitome of perfection, for instance pengenalan edm die sinking. It is because the process does not produce any heat-affected zones or stress recurring the workpiece, that may induce warping or cracking. Additionally, the task is non-contact, this means there is absolutely no threat of the tool breaking or shattering. This is why wire erosion safer than a number of other machining conventional.

With accumulation CNC machine tool manufacturing technologies, Taizhou Terui CNC Machine Co.,wire erosion has collected most technical expertise electroprocessing industry, developed manufactured high-performance machine tool products Taiwan, Singapore,European American technical teams.

Our company passed ISO9001:2008 quality certification ,CE certification every one products. And have wire erosion production experience.

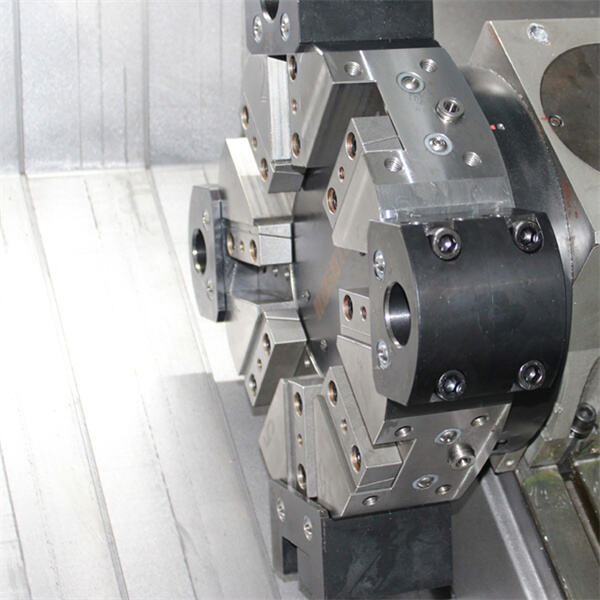

High quality, complete models long-lasting warranty main features these products. Machine specifications customized according customer needs, like non-standard models DK7740(45)F,DK7750(55)F,DK7763F,DK7780F,DK77100F,DK77120F even larger models. Company also produces +-30deg, +-45deg swing large taper machines CNC high-precision middle speed edm wire cutting machineswire erosion

Company perfect management good service, products sold well China,lndia,wire erosion,Korea,Ukraine,Russia,America,France,Bulgaria,Egypt,Germany, UK, Ecuador, Colombia, etc.

Wire erosion is really a process which is not at all hard. Plus, discover why Terui CNC's product is a customer favorite, such as edm drill head. The wire is given via a workpiece and attached with a charged power source (usually a generator). The energy supply applies a voltage distinction between the wire and the workpiece, generating an spark burns that are electric the material. The cable shall be advanced level through the workpiece to create the desired cut. The procedure is repeated prior to the desired form is set up.

Wire erosion is often found in different industries, including:

• Aerospace: The technique can be used to come up with parts that are complex plane machines along with other aircraft elements.

• Medical: Different implants, surgical instruments, and other devices are made that way.

• Automotive: Utilized for creating components for fuel injection systems, motor obstructs, and other components that are automotive. In addition, experience the innovation and reliability of Terui CNC's product, specifically molybdenum wire edm.

• Jewelry: Designers employ this solution to produce habits and this can be intricate designs in gold and silver coins.