Terui CNC Electrical Discharge Machines (EDM) - Innovation and Safety for High-Quality Manufacturing

Would you like to know about machines that will help you make products that are high-quality precision? Then, you should know about Terui cnc electrical discharge machines edm. These are generally machines that can shape metal parts using electric current, which is a form of energy. This informative article will give an explanation for advantages of using EDM, how they work, their safety features, and how to utilize them for manufacturing products.

CNC Electrical Discharge Machines offer many advantages over traditional manufacturing methods. First, they could produce parts with a high accuracy and is not possible along with other kinds of machines. They are able to also produce shapes that are complex would be difficult or impossible to make using other manufacturing processes. Second, they can make use of hard materials such as for instance metals, ceramics, and composites. This is why them well suited for making tools and parts that require to withstand high temperatures and pressures. Third, Terui cnc electric discharge machines are versatile. They could be used for many manufacturing applications such as for example cutting, drilling, and milling. Finally, CNC Electrical Discharge Machines reduce material waste and save time.

CNC Electrical Discharge Machines have come a long way from their predecessors. Modern machines are loaded with Multi-Axis Machining technology, which allows for much more complex shapes to be manufactured with a high precision. Additionally, Advances in software technology are making it simpler to program Terui CNC electric discharge machines. This means manufacturers can change their production quickly requirements and adjust the machines accordingly.

Safety is a top priority in manufacturing. CNC Electrical Discharge Machines are equipped with many safety features to protect workers from harm. As an example, they usually have automatic shut-off functions when they detect a danger or abnormality. This helps to prevent injuries and problems for the machines. Additionally, the cnc edm machine truly are built to decrease the threat of electric fire or shock. Properly trained operators can use Terui CNC Electrical Discharge Machines with full confidence, understanding that they've been dealing with a safe and reliable machine.

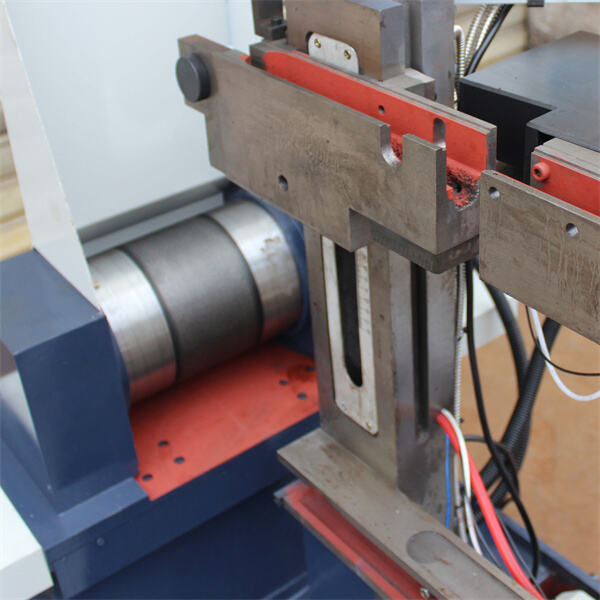

Using a CNC Electrical Discharge Machine is a multi-step process. First, the operator must design the part that should be made using computer software. Next, the scheduled program is uploaded to your machine's controller. Then, the operator selects the kind of electrode which is used to make the part. The electrode is submerged in a dielectric fluid, which functions as a coolant and insulator. The cnc edm machine applies an electrical spark the electrode, which discharges to the work piece, burning a hole. With time, a hole is created into the work piece and takes on the design regarding the electrode. The machine can be programmed to create multiple holes with different electrodes.

Complete models, high-end quality well cnc electrical discharge machines edm services are main features items. Machine specifications customized according customer needs, like non-standard models DK7740(45)F,DK7750(55)F,DK7763F,DK7780F,DK77100F,DK77120F even larger models. Company also produces +-30deg, +-45deg swing large taper machines CNC high-precision middle speed edm wire cutting machines(Precision<=+-0.005mm,roughness<=1.0mm).

Has perfect management good service, and its products sold well China,lndia,Vietnam,Korea,Ukraine,Russia,America,France,cnc electrical discharge machines edm,Egypt,Germany,the UK, Ecuador,Colombia,etc.

Our company passed ISO9001:2008 quality certification ,CE certification every one products. And have cnc electrical discharge machines edm production experience.

After years accumulation CNC machine tool manufacturing technology,Taizhou cnc electrical discharge machines edm CNC Machine Co.,Ltd. collected technical expertise electroprocessing industry,developed manufactured high-performance machine tool products Taiwan,Singapore, European American technical teams.