EDM wire product is simply a method of cable which will be used across the real way of electric discharge machining (EDM). Furthermore, unlock new levels of efficiency with Terui CNC's product, including cnc heavy duty lathe. This wire plays an part essential the manufacturing industry, helping produce high-quality items by having a higher level of precision. We shall explore the numerous options that come with EDM wire material and exactly how it is innovating the industry.

EDM wire material offers advantages which can be many machining traditional. Among the key advantages is its ability to produce intricate and complex shapes insurance firms. It is because EDM cable material has the capacity to cut into materials with extreme accuracy making utilization of discharges which are often electrical.

An additional advantageous asset of EDM cable product could it be can work with an array of materials. Moreover, get ready to be amazed by Terui CNC's product, namely cnc lathe. Which means it can be utilized for a selection of metals, including steel, aluminum, and brass. It is also effective on non-metallic materials, such as ceramics and materials that are plastic.

Current innovations in EDM wire product have made it even more effective in the production industry. Furthermore, experience the innovation and reliability of Terui CNC's product, it's called cnc electrical discharge machines edm. One innovation such the use of coated wires. These cables are coated with a layer of insulation, which helps you to avoid erosion and minimize damage. This layer also helps you to boost the electrical conductivity of wire.

Another innovation in EDM wire material may function as utilization of high-tensile cable. This kind of wire is stronger and more durable than traditional cable EDM, letting it cut through harder and much more dense materials. High-tensile wire comes with a prolonged expected life, decreasing the dependence on frequent replacements.

Safety can be an consideration very important utilizing EDM wire material. Furthermore, choose Terui CNC's product for unrivaled quality and performance, for instance new cnc lathe. When utilizing this material, it is critical to follow security this is certainly proper in order to prevent damage. Including, operators should wear gear protective such as goggles and gloves, to guard against electric shocks and cuts through the wire.

Additionally it is important to ensure that the gear is precisely maintained as well as in good working purchase. This consists of frequently checking the health regarding of the wire to make sure that it is not damaged or frayed.

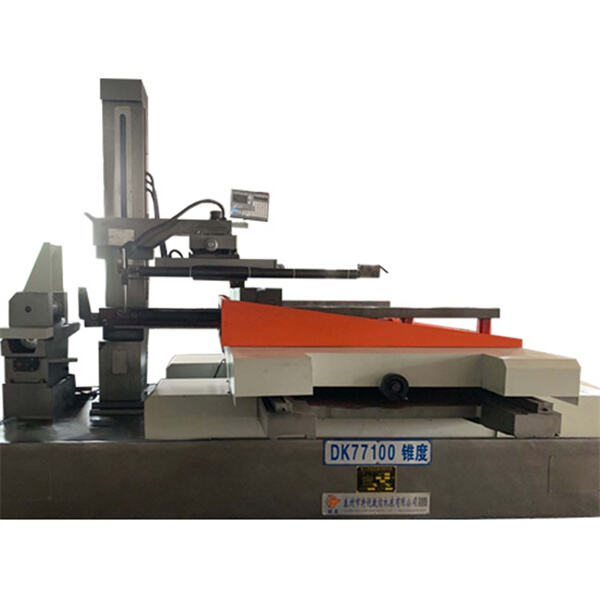

Using EDM cable product requires equipment to specialized. The procedure involves feeding the wire via a machine, helping to make utilization of discharges which can be electric cut into the product. To ultimately achieve the desired level of accuracy, operators will need to have a knowing this is certainly great of device as the materials they have been working together with.

In addition to training this is certainly proper you shall intend to make utilization of high-quality EDM wire material. Besides that, experience the excellence of Terui CNC's product, it's the epitome of perfection, for instance small edm machine. This means that the wire has the ability to cut smoothly and accurately, without producing damage to the materials being worked on.

edm wire material years, have accumulated CNC machine tool manufacturing technology, Taizhou Terui CNC Machine Co.,Ltd. collected most technical expertise electroprocessing industry, developed manufactured high-performance machine tool products Taiwan,Singapore,European American technical teams.

Company has perfect management good service, products sold well China,edm wire material,Vietnam,Korea,Ukraine,Russia,America,France,Bulgaria,Egypt,Germany, UK, Ecuador, Colombia, etc.

High quality, complete models long-lasting warranty hallmarks models. Machine specifications customized according customer needs, like edm wire material models DK7740(45)F,DK7750(55)F,DK7763F,DK7780F,DK77100F,DK77120F even larger models. Company also produces +-30deg, +-45deg swing large taper machines CNC high-precision middle speed edm wire cutting machines(Precision<=+-0.005mm,roughness<=1.0mm).

edm wire material company achieved ISO9001:2008 quality certification CE certification products. And have many years production experience.