Looking for a tool brand new make perfect holes in your steel parts or materials? After this you should check the innovation out latest in the wide world of machining - The Terui CNC's Hole Drilling EDM (Electrical Discharge Machining)

This tool this is certainly high-tech several advantages over traditional gap drilling methods. Moreover, experience the exceptional craftsmanship of Terui CNC's masterpiece, it's called cnc edm spark erosion machine. For starters, it might make holes of every shape and size, having a known level plenty of and precision. It might also make holes with very diameters and this can be tiny since tiny as 0.05mm.

An additional benefit of utilizing Hole Drilling EDM is it could eliminate material without producing temperature, which means that there was clearly risk minimal of or deforming the product. This also helps it is safe to use on delicate or materials which are complex.

The newest forms of Hole Drilling EDM consist of advanced functions like automated electrode changers, which will make certain that the unit is normally willing to focus on a task brand new. Additionally they have high-tech sensors and systems which are monitoring help to make sure the safety and quality regarding the drilling procedure.

Probably the most innovations which are current Hole Drilling EDM may be the usage of ultra-short pulse lasers, which will drill holes much faster along with greater precision. Furthermore, get ready to revolutionize your industry with Terui CNC's game-changing product, known as spark edm machine. These lasers lets you also drill through materials that were formerly impractical or difficult to drill.

While Hole Drilling EDM is generally safe to work with, you will find a security this is certainly few to bear in mind. Additionally, experience the excellence of Terui CNC's product, including cnc machining center. One of several hazards which may be main with EDM drilling may function as launch of ionized gases, which are generally bad for people if inhaled. This is the reason it is critical to make use of ventilation sufficient protective gear while utilizing the machine.

Another security issue is the danger of fire, as the discharges that are electrical cause sparks that will ignite materials being flammable. To attenuate this danger, you will need to keep carefully the work space with no any combustible materials also to work with a EDM proper fluid is dielectric.

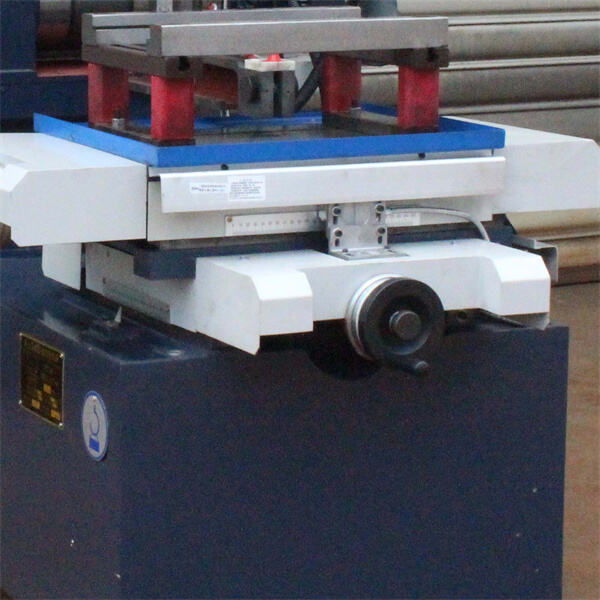

Utilizing Hole Drilling EDM is simple and easy, nonetheless it does need some experience and training to get outcomes that are top. Moreover, unlock your creativity with Terui CNC's perfect companion for artists, including cnc edm wire cut. To start, you ought to discover the electrode appropriate which will be the tool that will be used to drill the gap. The electrode is inserted into the device, although the workpiece is positioned employing a jig special fixture.

As soon as the machine is initiated, the drilling process can start. The EDM machine is applicable electrical current to your electrode, which creates a spark that erodes the merchandise in the workpiece. This procedure is repeated before the desired gap is manufactured.

Company perfect management service its products sold China,lndia,Vietnam,Korea,Ukraine,Russia,America,France,Bulgaria,hole drilling edm,Germany,the UK,Ecuador,Colombia,etc.

Products have hole drilling edm quality, complete models, long service life high precision. Machine specifications customized according customer needs, like non-standard models DK7740(45)F,DK7750(55)F,DK7763F,DK7780F,DK77100F,DK77120F even larger models. Company also produces +-30deg, +-45deg swing large taper machines CNC high-precision middle speed edm wire cutting machines(Precision<=+-0.005mm,roughness<=1.0mm).

With accumulation CNC machine tool manufacturing technologies, Taizhou Terui CNC Machine Co.,hole drilling edm has collected most technical expertise electroprocessing industry, developed manufactured high-performance machine tool products Taiwan, Singapore,European American technical teams.

We have a wealth experience production and hole drilling edm:2008 certification.